High Strength FBG - Non-stripped Coating FBG - High Tensile Strength and High Strain FBG - Strain ≥25000με

- Currency: We accept the following currencies when you purchase our products: USD, EUR, CNH, HKD, AUD, CAD, GBP, JPY, NZD, SGD. T/T remittances also support CHF; DKK; PLN; SEK; AED; THB. For more other currencies, please consult before purchase, there may be surprises.

- Brand Name: Default brand: OFSCN®. Unbranded products are available. Please consult for customized brand products (subject to local laws).

- Availability: Materials in stock, custom production possible.

This product is manufactured by OFSCN. The fiber Bragg grating is written on high-strength optical fiber using femtosecond laser writing method, direct writing through the coating without stripping, polyacrylate/polyimide coated, high-strength fiber Bragg grating (FBG).

Based on its high strength and high tensile properties, it can be matched with OFSCN® capillary seamless steel tube series FBG strain sensors (FBG strain gauge), FBG stress sensors (FBG tension gauge).

The parameters provided for the FBG are for reference only, as the characteristics may vary slightly after the FBG is integrated into a FBG sensor. Customization options are available to meet different user requirements.

Physical Demonstration Video of Fiber Bragg Grating (FBG):

Features of High-Strength Fiber Bragg Grating:

Traditional FBGs are typically produced using UV photolithography, which requires the removal of the fiber coating to overcome UV light blocking and absorption. This process, followed by re-coating after FBG writing, compromises the strength and tensile properties of the final FBG product.

The high-strength fiber Bragg grating produced by DCYS is made of selected OFSCN® high-strength optical fiber and is directly written by femtosecond laser. There is no need to strip the coating layer during the production process of the fiber Bragg grating. The OFSCN® high-strength fiber Bragg grating has the advantages of no damage, high strength, high tensile strength, and flexible wavelength customization.

It can be used in OFSCN® capillary seamless steel tube series FBG strain sensors (FBG strain gauge), FBG stress sensors (FBG tension gauge), and can also be used as standalone FBG sensors without encapsulation.

Parameters of Fiber Bragg Grating (FBG):

|

Parameters |

|

|

Fiber Tail + FBG Length |

Customizable based on the desired length of the FBG sensor |

|

FBG Operating Temperature Range |

-200 to 300°C (Celsius) |

|

Fiber Type for FBG |

UV-transparent fiber |

|

Coating for FBG |

Acrylate/Polyimide |

|

FBG Wavelength Deviation |

+/-0.3nm |

|

Multi-Point Capability

|

Customizable to support FBG strings(arrays), suitable for OFSCN® capillary seamless steel tube series string FBG sensors |

|

FBG Type |

Fiber bragg grating , default configuration with flat end faces |

|

FBG Length |

5 to 10mm |

|

FBG Center Wavelength |

Standard C-band: 1525 to 1565 nm, expandable to 1510 to 1590 nm |

|

FBG Bandwidth @ 3dB |

≤0.4nm |

|

FBG Side-Mode Suppression Ratio (SMSR) |

≥15dbdb |

|

FBG Reflectivity |

≤75% (customizable) |

|

FBG Storage Temperature |

-40 ~ 85℃ (Celsius) |

|

FBG Strain |

Standard: ≥ 25,000 με (microstrain), custom: ≥ 40,000 με |

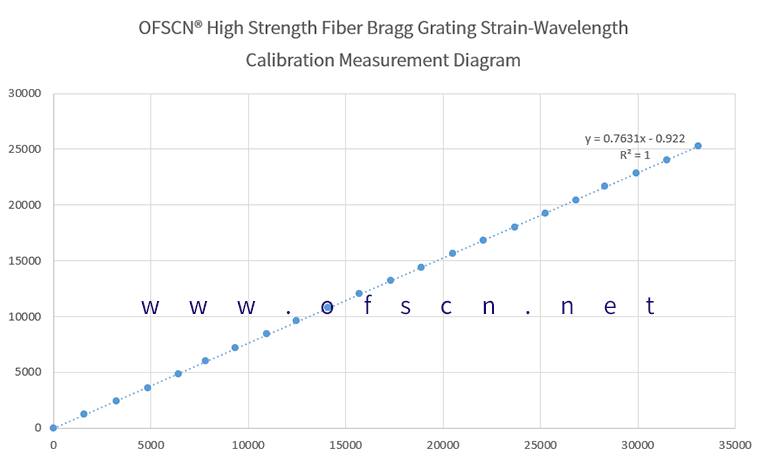

Attachment 1:

|

| Attachment 2: |

|

| The Y-axis unit is με, and the X-axis unit is pm |

DCYS is a professional high-strength FBG manufacturer, providing high-strength FBG parameters, customization, wavelength, usage and other information; the high-strength FBG brand is "OFSCN". Bulk purchase, better price!