Fiber Bragg Grating Sensing Technology Encyclopedia - FBG FAQ - FBG Sensor FAQ - FBG Demodulator FAQ - FBG Common Application Problem Analysis

FBG String/array Sensor- Distributed Fiber Bragg Grating Sensors - Quasi-Distributed Fiber Bragg Grating Sensors - Concept of Multi-Point FBG Thermometers

This article introduces the concept of distributed FBG sensors (also known as quasi-distributed FBG sensors, FBG string/array sensor, array FBG sensors, or multi-point FBG thermometers) and answers the question, "How many FBG can be integrated into a distributed FBG temperature sensor?" It also introduces the capability of OFSCN® Capillary Seamless Steel Tube FBG Sensors to encapsulate FBG arrays (FBGs) for multi-point temperature measurements and provides actual product images and measurement results.

1. Concept of Distributed FBG Sensors and Number of FBGs (Distributed FBG Sensors)

A FBG string/array sensor- carving multiple FBGs with different wavelength on an optical fiber to form a FBG string/array, and encapsulating it to be a FBG sensor. FBG string/array sensor is also referred to as Distributed FBG Sensors, Quasi-Distributed FBG Sensors and Multi-Point FBG Thermometers.

A FBG string/array sensor allows simultaneous measurements of multiple points and parameters using a single sensor.

In theory, you can carving an infinite number of FBGs on a single optical fiber, only need is that different FBG with different Bragg wavelength.

|

|

|

Figure 1 |

Figure 2 |

However, in practice, there are limitations due to the broadband light source and the receiving detection module of the FBG demodulator. The wavelength range is limited. Additionally, the FBG's wavelength will change with temperature and strain. Therefore, it is necessary to ensure that there is no overlap between the FBG wavelengths . This allows the FBG demodulator to distinguish different FBGs based on their respective reflection wavelengths.

Another factor that affects the number of FBGs is the available power when receiving the reflected FBGs. This depends on the demodulator's transmission power, losses along the path (including bending losses, connector losses, joint losses, and fiber length losses), and the reflectivity of the FBGs.

Hence, several factors influence the number of FBGs that can be used. Generally, for the commonly used C-band, it is recommended to use no more than 20 FBGs on a single distributed FBG sensor (It is necessary to analyze different applications).

|

|

Figure 3 |

2. Quasi-Distributed Fiber FBG Grating Sensors and Physical Diagram of FBG Strings/Arrays ( FBG String/Array Sensors)

OFSCN® has extensive experience in packaging FBG arrays and can provide customers with distributed FBG sensors (also known as quasi-distributed FBG sensors). An example is shown in the figures below (Figure 4 and 5), where eight FBGs with different wavelengths are inscribed on a short length of optical fiber, enabling simultaneous measurements of eight points.

|

|

Figure 4 |

|

|

Figure 5 (The image above shows the wavelength distribution of an optical fiber with eight different wavelength FBG array using an optical spectrum analyzer.) |

|

|

Figure 6 |

3. What is FBG array

"FBG array" refers to a Fiber Bragg Grating (FBG) array. FBG is a fiber optic sensor technology that utilizes the grating structure within the optical fiber to measure physical quantities such as strain, temperature, displacement, force, vibration, and more.

An FBG array represents a configuration where multiple FBG measurement points are distributed or arranged on one or multiple optical fibers. This can form a single-fiber OFSCN (Optical Frequency Scanning) FBG sensor with multiple measurement points or a multi-fiber OFSCN FBG sensor with multiple measurement points on each fiber.

By deploying the aforementioned OFSCN FBG sensors at various positions, an FBG array allows simultaneous monitoring of multiple measurement points, providing comprehensive three-dimensional environmental information on the OFSCN FBG demodulator software platform.

The applications of FBG arrays are diverse, especially in the field of structural monitoring. For instance, deploying an FBG array on bridges or buildings enables real-time monitoring of structural deformations, strains, and vibrations. Additionally, FBG arrays find utility in areas such as oil and gas pipelines, wind turbine blades, etc., enabling high-precision measurements at multiple points in complex environments.

In summary, an FBG array, incorporating multiple FBG sensors distributed at different positions, offers a flexible and high-precision fiber optic sensing solution suitable for various application scenarios.

The concept of an FBG array integrates Fiber Bragg Grating, FBG sensors, and the OFSCN FBG demodulator software platform.

4. What is fbg sensor array, and what are the differences with fbg array

"FBG sensor array" and "FBG array" emphasize slightly different aspects.FBG Sensor Array:

- Definition: FBG sensor array refers to the distribution or arrangement of multiple FBG sensors in a certain area, which can be on one or multiple Fiber Bragg Grating sensors.

- Features: This term emphasizes the multiple configuration of FBG sensors, covering the overall layout of multiple grating sensors, not just focusing on a single Fiber Bragg Grating sensor.

FBG Array:

- Definition: FBG array typically refers to the configuration of multiple FBG measurement points on one or more fibers, forming an array structure.

- Features: This term emphasizes the array nature of FBGs, encompassing multiple Fiber Bragg Grating measurement points on a single fiber or on multiple fibers.

In practical use, these two terms are often interchangeable because they both denote the arrangement of multiple FBG measurement points in an area to achieve multi-point measurement or monitoring.Therefore, the difference between them is mainly reflected in the emphasis on whether the FBGs are individually highlighted. In some contexts, "FBG array" might emphasize the overall structure and configuration of the entire array, while "FBG sensor array" might place more emphasis on the layout of individual sensors.

5. Use the OFSCN FBG demodulator to graphically display the fiber grating sensing array (multi-point fiber Bragg grating sensor/FBG String/Array Sensors) to achieve distributed measurement

You can use the OFSCN fiber Bragg grating demodulator to graphically display the fiber Bragg grating sensing array to achieve distributed measurement. Here are some examples(taking temperature measurement as an example):

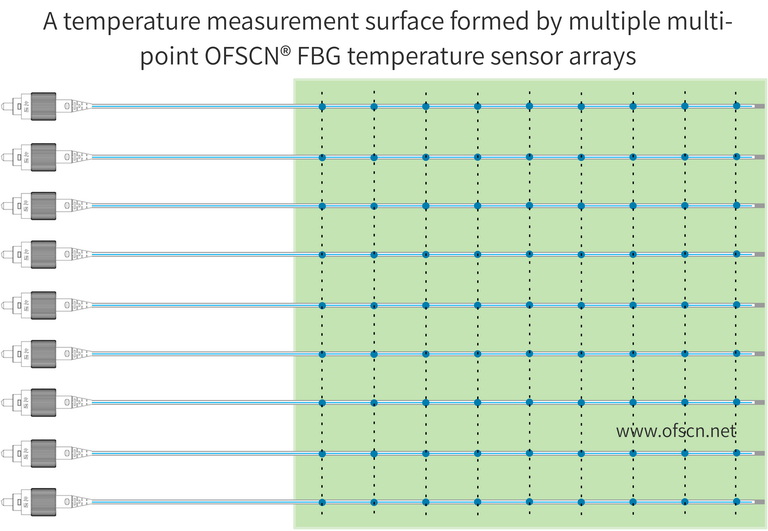

A, The temperature measurement plane formed by multiple OFSCN FBG temperature sensors with multiple measuring points is shown as follows:

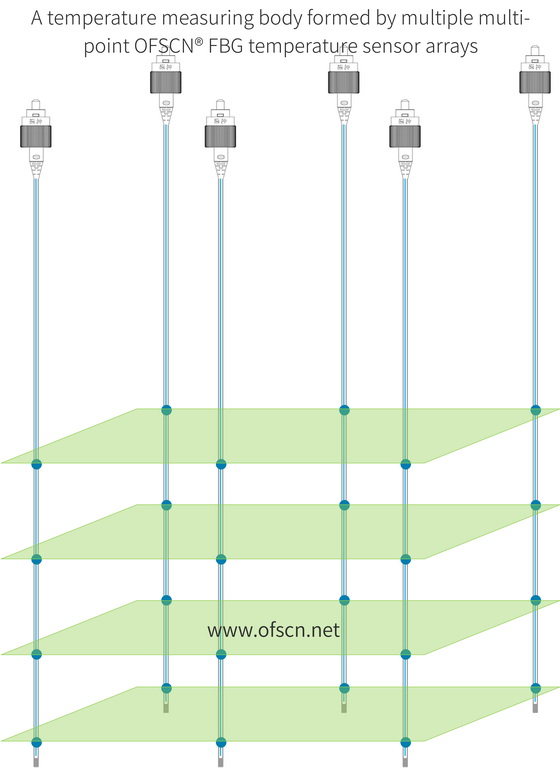

B, The three-dimensional temperature measurement diagram formed by multiple fiber Bragg grating temperature sensors with multiple measuring points is shown as follows::

C, In the OFSCN Fiber Bragg Grating Interrogator, you can also map these fiber Bragg grating sensing measuring point arrays to the real world by uploading photos:

Our philosophy is: "OFSCN®, make optical fiber stronger!"

DCYS is a professional string FBG sensor manufacturer, providing string FBG temperature sensor, quasi-distributed FBG strain sensor, multi-point FBG stress sensor, FBG sensor network array and other information; The brand of string FBG sensor is "OFSCN".

One comment

-

Good post. I definitely appreciate this website. Stick with it!